Advance Shipping Notice (ASN)

This message tells a buyer when the goods will be shipped, how they’ve been packed and the estimated arrival date. This can also referred to as a Delivery Notice or Despatch Advice.EDIFACT

This stands for Electronic Data Interchange For Administration, Commerce and Transport. It’s an international EDI standard that was developed by the United Nations. Types of EDIFACT messages include 96A and D01B. They’re commonly used in the retail industry here in Australia.Translation

The conversion from one file format to another.ERP system

Also known as an Enterprise Resource Planning system. This software is used by companies to manage much of their business activity – they’re like an accounting package on steroids. Examples of ERP systems include SAP, Oracle, Pronto, JD Edwards and Sage.Gateway

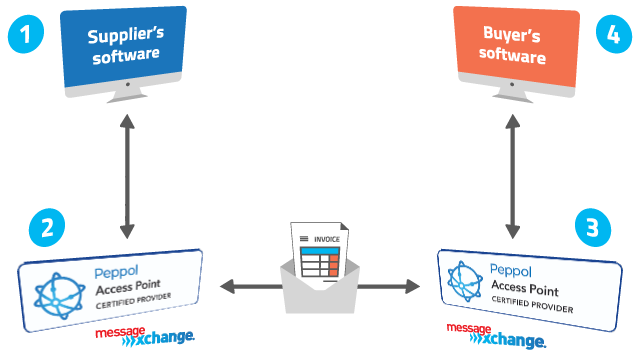

A Gateway is the central point that enables the exchange of messages between systems (often provided by a value added network, or a VAN). It mediates the differences between your software and those of your trading partners. If you think of a hub and spoke model, the Gateway is the hub, and you and your trading partners are the spokes. Through MessageXchange, Gateways can be configured per customer to have specific business rules, mappings, error handling and more.GLN

A Global Location Number (GLN) is a unique number that is assigned to locations to enable them to be identified worldwide. These global location numbers can be used to identify any legal, physical and functional locations. They’re issued by the standards body GS1. GLNs are also used in the EDI to identify a business to exchange messages with.GS1

GS1 is a worldwide not-for-profit that encourages the use of standards in business to create efficiency in supply chains and overall business. GS1 develops and publishes standards for barcodes, product data and EDI. They’re the organisation that issue GLNs and GTINs.GTIN

This stands for Global Trade Item Number. It’s a unique identifier for each product. If you look at a barcode, they’re often GTINs. Here in Australia, they’re issued starting with a 93 or 94.iDoc

iDoc stands for intermediate document. It’s a data structure for electronic data interchange between application programs written for the popular SAP business system or between an SAP application and an external program.Mapping

Mapping refers to translating, or converting, one file format to another. For example, if your software outputs a CSV file and your trading partner requires an EDIFACT file, your EDI VAN would ‘map’ the CSV file to EDIFACT.Message type

An structured set of data covering the requirements for a specified type of transaction, for example, an invoice or purchase order.MIG

A MIG, or message implementation guide, details the file structure that your trading partner requires. A MIG is usually written for each message type required by that trading partner. You can see examples of MIGs on our website: home.messagexchange.com/resources/migs/Network service provider

A company that maintains an EDI network on behalf of businesses, also known as a value added network. They offer its services and capabilities to others for a fee.SFTP

Secure file transfer protocol. A network protocol that provides file transfer over the web securely using authentication and encryption.SSCC (serial shipping container code)

An 18-digit number that is used to identify logistics units. It allows whoever it is receiving the goods to track them throughout the journey, and gives them more insight into what’s inside a shipping unit.SSCC label

The label is linked to the ASN. The label has one or more barcodes on it, which includes the SSCC number. Often in retail, these are scanned when receiving the goods to mark them as received in the retailer’s software and to identify exactly what’s in the package.Transmission protocol

Transmission protocol refers to how your messages will get from your software to your VAN. Some examples include sFTP or AS2. Choosing your transmission protocol largely depends on the level of security required as well as the need for timely, real-time information.VAN

VAN is the acronym for Value Added Network; they’re the company that provides an EDI service. VANs enable your EDI capability to be scalable because they sit at the core of your trading network and enable the routing of messages, which reduces the impact of change. At MessageXchange we combine the VAN capability with Gateway capability so message routing can be combined with message mapping, business rules business intelligence reporting, custom error handling, notifications and the top level of security.Web-based EDI

A method of EDI that allows users to send and receive EDI from an internet browser portal. It does involve manual inputting of information.XML

The abbreviation for extensible markup language – it is a file format commonly used by software to export and/or import data. If you want to learn more about EDI for your business, request a call back from our EDI experts below.Request a call

Chat with one of our experts

Just fill out your details below and we'll be in touch within one business day.

It uses a standardised framework, Peppol[vc_column_inner width="1/3" css=".vc_custom_1611113989632{padding-top: 0px !important;padding-right: 20px !important;padding-bottom: 0px !important;padding-left: 15px !important;background-color: #eeeeee !important;}"]Value Added Network (VAN)

It uses a standardised framework, Peppol[vc_column_inner width="1/3" css=".vc_custom_1611113989632{padding-top: 0px !important;padding-right: 20px !important;padding-bottom: 0px !important;padding-left: 15px !important;background-color: #eeeeee !important;}"]Value Added Network (VAN)