- cost savings

- shortened procure-to-pay cycle

- better data accuracy

- less manual handling

- better visibility into your supply chain

- better customer service.

Not understanding EDI and how it works

Simply put, EDI (electronic data interchange) is the exchange of business information directly between business software. Think of a purchase order being created in one company’s accounting package, and it ‘magically’ appears in the supplier’s software; no email, no PDF, no manual data entry. Well, it’s not magic, it’s EDI! Check out our whitepaper to learn all the basics. EDI can be pretty technical so this often makes it a little daunting for businesses. There’s also a sense of if you don’t have expertise you’ll have trouble implementing. The fact is, EDI providers, like MessageXchange, will always be there to clarify a lot about how it works and work with the relevant internal teams to make the process seamless.Having unrealistic expectations

EDI requires clear expectations in terms of costs, timelines, internal operations and of suppliers. Rome wasn’t built in a day! When it comes to EDI, planning at the beginning is everything. This will give a clear direction for implementation and help assess how things are tracking compared to your targets. Keep these clear with your provider and hold them to it. The planning stage should also set clear expectations of who is responsible for what when EDI is implementation. Something else you can do is to get a clear understanding of price from your provider. All providers have different pricing models, make sure you find the one that suits your business most.The capability of your supply chain

Your supply chain is critical to any EDI project. It can often make or break a project. So it can seem like a big barrier if you have difficulty getting suppliers onboard. But there are definitely ways around this. The number one thing to do when looking at onboarding suppliers is to segment them into groups and use this to stage your onboarding process. There’s no right or wrong way to segment your suppliers. It can be according to their readiness for EDI, maybe their size, whatever you like. As you’re onboard each segment it will give you an understanding of your progress. Another great way to get around suppliers not onboarding is by giving them options. If they’re already using EDI they can just integrate with your EDI solution. If they’re not using EDI, you can offer them a web portal solution, like Colladium. It makes it easier for suppliers, particularly smaller ones, to send and receive EDI messages all from a web browser.Lack of resources

EDI is often linked with being costly and time intensive to set up but that’s changed a lot. These days businesses with no previous EDI experience are getting set up easily and quickly. EDI providers, like MessageXchange often step businesses through the whole process and even take care of critical parts. MessageXchange can create automated compliance testing solutions that test the EDI messages of suppliers on a portal to make sure it adheres to all EDI requirements. This saves you time and also saves your staff from having to contact suppliers one by one to organise testing. Need more help getting ready for EDI? Ask our experts by getting in touch below.Request a call

Chat with one of our experts

Just fill out your details below and we'll be in touch within one business day.

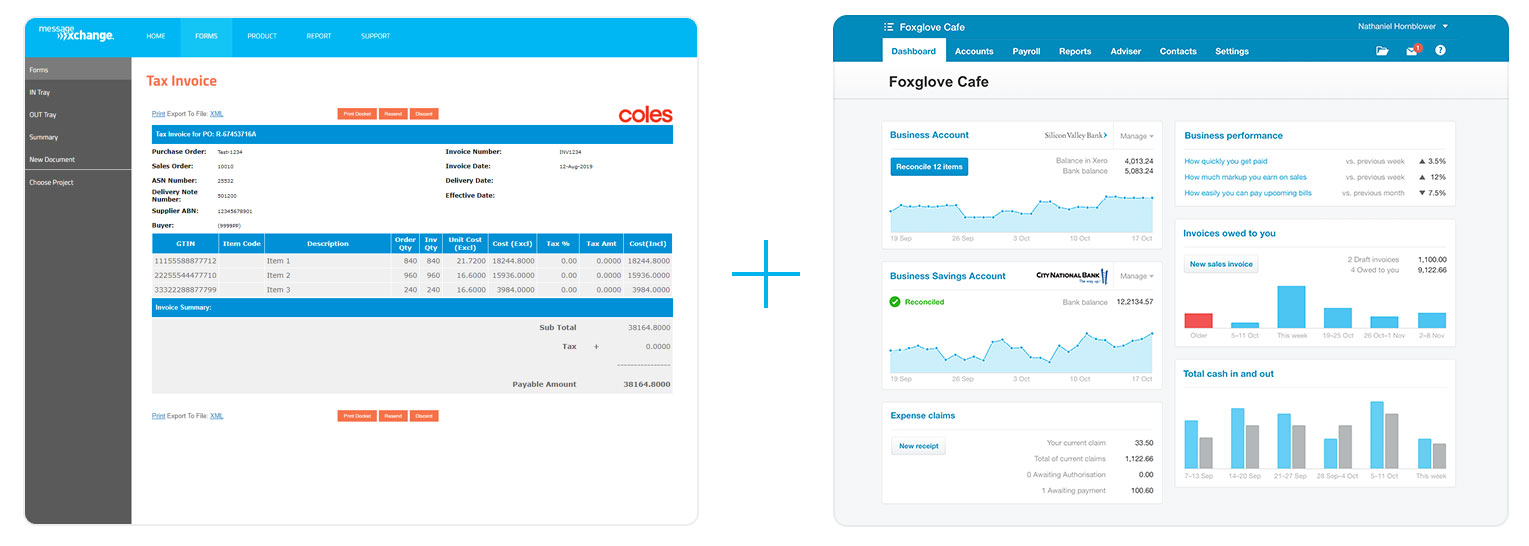

If you choose to go with our FormXchange product, you can even automate the process one step further. By turning on the integration between FormXchange and Xero, you can sync the invoices you enter in the EDI portal (FormXchange) directly to Xero, so your invoices are always up-to-date in your accounting software.

That means whenever you send an invoice to your customer on FormXchange, a copy will go to them, as well as to your Xero account. It’s that simple.

If you choose to go with our FormXchange product, you can even automate the process one step further. By turning on the integration between FormXchange and Xero, you can sync the invoices you enter in the EDI portal (FormXchange) directly to Xero, so your invoices are always up-to-date in your accounting software.

That means whenever you send an invoice to your customer on FormXchange, a copy will go to them, as well as to your Xero account. It’s that simple.