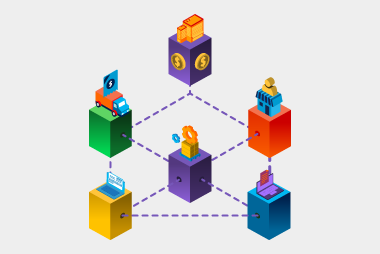

What Is EDI?

Simply put, EDI (electronic data interchange) is the exchange of business information directly between business software. Think of a purchase order being created in one company’s accounting package, and it ‘magically’ appears in the supplier’s software; no email, no PDF, no manual data entry. Well, it’s not magic, it’s EDI!Starting at the source: manufacturers and suppliers

The journey begins with the people who make or source the goods – manufacturers and suppliers. When a retailer or distributor places an order via EDI, it lands straight in the supplier’s system, ready for processing. Whether the supplier is sourcing locally or globally, EDI helps them:- confirm product availability

- respond quickly to order changes

- manage lead times more effectively

- send digital confirmations and updates.

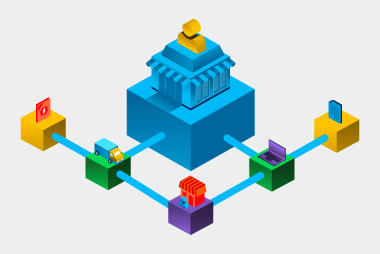

Through the supply chain: warehousing and distribution

Once goods are packed and ready to ship, advanced shipping notices (ASNs) are sent via EDI to alert the next link in the chain. These ASNs provide details on what’s being delivered, in what quantities and when. That allows receiving teams to prepare and improves inventory accuracy. With standardised labels and barcode integration (like SSCC labels), goods can be tracked from origin to shelf with minimal manual input.At the retailer: smarter ordering and replenishment

Retailers can create orders and send them directly to their suppliers’ software. Retailers can get responses back from suppliers to confirm if they can fulfill the order and also receive invoices directly into their software. You can take it even further with the information you get from EDI. When stock drops below a set threshold, EDI can trigger and order automatically to suppliers or distributors, reducing out-of-stocks and avoiding overordering.EDI has applications all across the retail supply chain. Want to learn more about implementing EDI? Get in touch with our experts.Request a call

Chat with one of our experts

Just fill out your details below and we'll be in touch within one business day.