Automate your supply chain

If you’re still emailing orders and invoices, you’re probably doing more data entry than you need. It might look like this:- Buyer manually enter purchase order in their software.

- Buyer send order to supplier via email or post.

- Supplier receives order and manually enters the purchase order details into their software.

- Supplier manually enters the invoice into their software.

- Supplier send invoice to buyer via email.

- Buyer manually enters the invoice in their software.

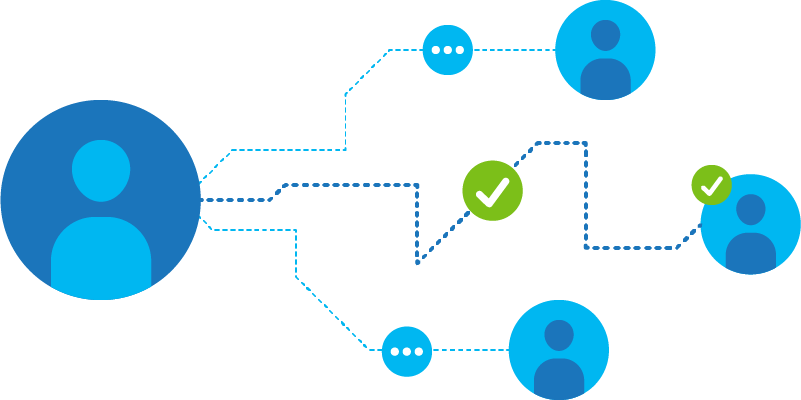

- The buyer enters the purchase order in their software.

- It’s automatically sent to the supplier and appears in their software.

- The supplier actions the PO and then creates the invoice in their software and sends back to the buyer.

- The invoice then appears in buyer’s software.

Automate your accounts payable

Often errors are made by incorrectly entering invoice data. Not only does it stop staff from working on higher value tasks, but it can be costly to rectify the errors. EDI makes it easy to implement two- or three-way matching. Two-way matching involves automating the process of checking invoice quantities and values against that on the purchase order. Three-way matching goes one step further and also checks delivery information to verify the invoice is for the same quantity that’s been sent. It not only saves your team time, but can also reduce labour costs.eInvoicing

eInvoicing allows you to send invoices directly from your software to your partners’. It uses the international Peppol standard to send and receive eInvoices. It’s different from EDI in that you only need to connect to the Peppol network through an Access Point to you can exchange eInvoices with anyone else in the network. eInvoicing produces savings by:- Reducing the amount of work required send invoices. This reduces costs and allows your accounts receivables teams to focus on value adding activities.

- Helping increase cash flow for suppliers by speeding up the preparation and sending of invoices.

- Helping buyers speed up their payment processing, allowing them to make good on early payment discounts.

Automate goods receipt

Receiving goods from suppliers can be a time-consuming process. It can be difficult to know when goods will arrive and therefore can be difficult to plan. This only wastes time, money and resources. A way to make savings in this area is to ask suppliers to send you advanced shipping notices (ASNs) directly to your software through EDI. ASNs detail what your supplier is sending, how it’s packed, when it’ll arrive and more. This allows you to prepare to have the right warehouse staff to receive the shipment, saving you money on labour and allowing you to allocate staff more efficiently. Receiving ASNs from suppliers will also allow you to automatically record stock as it comes in. SSCC labels (the barcodes on each unit your supplier sends) correlate to a unit (e.g. a box or container) on the ASN. Scanning each pack as it comes in reduces manual inputting, saving your warehouse team time and reducing the risk of costly inputting errors. It also means your stock levels will always be up-to-date.Consider alternative models with suppliers

A large cost for retailers can be for warehousing and logistics and that’s why savvy retailers are turning to drop shipping. The drop shipping model sees the supplier hold stock. When the retailer makes the sale, they pass the details onto the supplier to ship the order to the customer. EDI can create even more efficiency in this model by:- Sending orders directly to suppliers when the order is placed

- Reducing errors and the related costs

- Keeping you updated on suppliers’ stock levels, helping you avoid shortages of goods.

Request a call

Chat with one of our experts

Just fill out your details below and we'll be in touch within one business day.